YO TANA MACHINE TOOLS P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to YO TANA MACHINE TOOLS P.LTD.

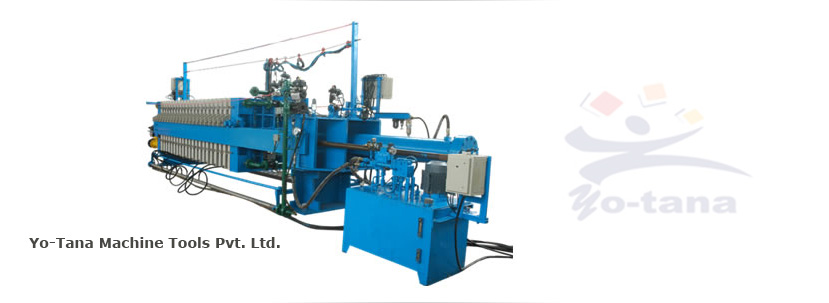

Conventional Filter Press

Conventional Filter Press

Back to Product

Filter presses are extensively used to separate solids from liquids in a wide range of applications.

The liquid solid mixture is pumped into the filter press, which is made up of a number of recessed filter plates forming chambers. The plates are supported in a fabricated steel frame and is held closed by a force exerted from a hydraulic ram mounted in the frame work at the end of the machine.

Each filter plate is covered by a filter cloth that retains the solid particles, but allowing the liquid to pass through and exit through the ports in the filter plate.

The particles retained gradually build up on the surface of the filter media and after a period of time eventually form a solid cake.

As the cake forms the pressure within the filter press the pressure rises as the filtrate has to pass through the already partially formed cake to exit the chamber. It becomes increasingly more difficult to continue pumping as the press is unable to accept more solids. At this point the feed pump is stroking infrequently and the filtrate flow from the filter press has considerably reduced or completely stopped.

At this point or at a pre determined filtration time or pressure being achieved the cycle is terminated and the fully formed filter cake is discharged.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.